It lacks essential production info including batch components, mixing time, and temperature. Furthermore, it lacks essential info to investigate batch failures.

Building workers promptly quit their operate to fix the discovered structural flaw to ensure the building's integrity and basic safety.

Also, a strong CAPA procedure can aid providers in meeting authorized obligations and regulatory requirements.

A corrective and preventative action program can be a necessity in regulatory environments. But it’s not possible to help make continual good quality improvements should you’re employing an advertisement hoc CAPA program that slows down good quality and generation procedures.

CAPA principles could be applied to troubles involving software program bugs, protection lapses, and procedure failures in the knowledge technology sector. IT firms can enhance program reliability and decrease downtime by implementing corrective and preventive measures.

To begin, both of these actions focus on differing types of troubles. A corrective action concentrates on resolving concerns which the Group or workforce is by now going through or has skilled.

Each and every pharmaceutical and medical device manufacturer together with other existence science Corporation need to put together CAPA procedures, that adjust to applicable regulatory requirements.

Among a CAPA report’s primary features is to make sure a corporation complies with regulatory and firm expectations. It helps corporations apply protocols which are created to fulfill compliance and regular necessities.

Nurses and Medical practitioners swiftly administer the necessary cure to alleviate the individual's signs or symptoms and prevent even more wellbeing complications.

It should really elucidate the specified goals website following analyzing details. Documenting the root lead to will aid bettering the solution and its implementation. The subsequent phase should be to create an action prepare. Ideally, a cross-practical workforce need to be involved with the CAPA to layout and put into practice an effective Remedy. When the approach is prepared, it really should be implemented. The prepare need to be shared Using the relevant groups, get their buy-in, and practice them in case any new competencies are necessary. Checking and tracking is the ultimate move that assures the implementation is effective and that the CAPA Option delivers the desired results.

The corrective actions are immediately needed to fix the problems in the method. It tends to make absolutely sure that the process returns to ordinary Doing work parameters. Corrective actions tend to be carried out before the Root Bring about Assessment phase.

An outstanding administration process, a structured and systematic tactic for running procedures, website solutions, and expert services to fulfill shopper specifications and regulatory standards, is basically entire with CAPA.

The quality Division is answerable for getting ready, reviewing, and approving the CAPA varieties through the entire Group.

In case you have an interest in automating and strengthening the traceability within your CAPA we recommend you e book a personalized item demo and talk to our professionals.

Jenna Von Oy Then & Now!

Jenna Von Oy Then & Now! Gia Lopez Then & Now!

Gia Lopez Then & Now! Sam Woods Then & Now!

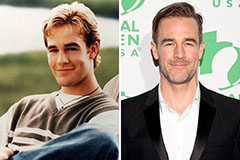

Sam Woods Then & Now! James Van Der Beek Then & Now!

James Van Der Beek Then & Now! Kane Then & Now!

Kane Then & Now!